The ground heat exchanger one of the main components of a geothermal heat pump. The heat pump receives heat of the Earth’s interior through the heat exchanger. And the efficiency and reliability of the heat pump depends on the proper design and installation of the heat exchanger. Today a very large number of heat exchangers.

All of them can be divided into several groups:

1. Horizontal heat exchangers or collectors. This group of exchangers is simple installation and low cost. However, the main disadvantages is the fact that installation of such devices needs a large area, where there will be buildings and spaces. Heat exchangers are installed in a depth of soil freezing. Depth depends on location and varies from 1 to 3m. The upper ball of soil can be compared with the battery, because they accumulate heat from the sun. But the temperature of the accumulated heat depends on the time of year, so it is unstable and fluctuates all year round. Such fluctuations affect the efficiency of the pump, because at a depth of about 2m, the annual temperature variations are observed from +7 to +13 degrees. Heat from the ground depends on many characteristics such as: the area in which is situated a heat exchanger, depth of installation, soil quality and other factors. To a horizontal heat exchanger is effectively removed heat from the ground, pipes should be mounted at a distance of not more than 0.7 m apart. If the heat exchanger consists of multiple contours, they should be approximately equal in magnitude.

2. The vertical probe or heat exchanger. It is installed at a greater depth from 20m to 300m. To such great depths there is no temperature fluctuations, so it is stable throughout the year and not depend on the season (8-10º). Such a probe size diameter can reach from 120 to 200mm. The probe is often used a tube of plastic with a diameter of 32mm. For installing the probe you need to drill a well. It is set in two loops of the probe. The space between the loops is filled with a special substance with high conductivity. The efficiency of the probe is more than manifold, but it also depends on the quality and characteristics of the soil (presence of groundwater, soil moisture, etc.).

This group of exchangers is faced with a reduction in the temperature of the soil within 2-3 years of their use. This happens due to the fact that although soil heat and renewable source, but spending it faster than it can recover. The optimum pump run time is 1800 hours per year. Observations have shown that the first years of use of the probe, the temperature of the soil around the probe decreases sharply, but longer every year lowering the temperature decreases. This affects the efficient operation of the pump. If the time of annual work exceeds 1800 hours, there is a risk of lowering the temperature around a well or even freezing in some areas. And freezing is directly related to the use of a vertical heat exchanger. Because during the freezing of some sections of the ground, he sedesa, which can lead to the destruction of the probe and disturbance of the microclimate of the soil.

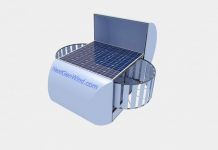

3. Other heat exchangers. These include spiral heat exchangers and baskety. It’s like a hybrid of the two previous groups. Such heat exchangers have properties horizontal, and method of installing vertical heat exchangers. But in contrast to the vertical, they are placed at a shallow depth (up to 5m).