Osmotic power plant is so named because the work is based on the salinity gradient of fresh and sea water. The greater the gradient the more energy is produced. Osmosis is very strong pressure that is created can generate a water column height of up to 120 meters. The world’s first osmotic power station was built in Norway in 2009. For the development and implementation of this idea scientists have spent the last 10 years. Energy use of salt is now very promising.

Power plants of this type based on the physical phenomenon of osmosis. This process of diffusion in the more concentrated solution less concentrated solution.

These power plants use different levels of salt concentration in marine and fresh water.

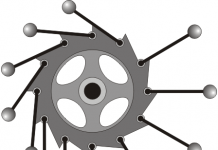

The principle of operation of the power plant.

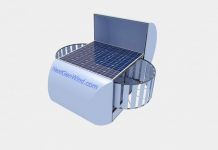

The whole plant is a chamber separated by a semipermeable membrane. One part of the chamber is injected salt water and the other fresh. The molecules of fresh water begin to strive in the direction of the camera, where sea water, because that’s where the salt concentration is much higher. In part of the chamber with sea water increasing, and with it the pressure. This pressure is osmotic. Osmotic pressure affects the turbine. She starts to rotate and drives the generator, and it starts to generate electricity.

The problem of membranes.

The basis of the effectiveness of osmotic power is the membrane. The membrane represents not a straight wall, and a long roll in the cylindrical housing. The first membranes used were the membranes of the Loeb-Suranjana. But the use of this membrane for a long time did not give positive results. It required absolutely pure water. Therefore, the chamber water needed to provide purification system. In such a system consisted of a primary coarse filter, and then cascade to other filters, and a powerful pump which cleans the surface of the membrane. Another factor that influenced the use of this membrane is its high cost. A team of scientists analyzing existing materials, I came to the conclusion that their manufacture of modified polyethylene will be much more efficient. It was a real breakthrough that opened the future of osmotic power. As of 2015, the membrane used in the Norwegian plant was to produce up to 5Ват/m2. We are working on the development of new more efficient membranes. The application of material based on nanotubes, allows to obtain from 1 m2 to 4 kW. This result is many times the efficiency of traditional energy sources. And the use of the graphene film on the efficiency of equal to 10 kW/m2.

The world’s supply of osmosis is very large. The use of 10%, could provide half of Europe’s electricity and about 1.5 TWh/hours. Osmotic power plant is environmentally friendly and does not depend on climatic or weather conditions. And the main fuel for generation is always in excess, as 94% of our planet covered with water. Of the shortcomings can be identified only that a plant can only be built at the mouths of rivers.

Further development of osmotic power industry depends entirely on whether it developed a highly efficient membrane with the next 10 years.